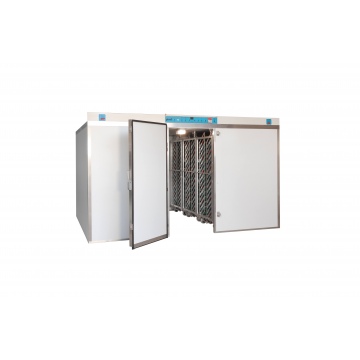

The Bristol S180 setter has a weekly pheasant egg setting capacity of 12180 eggs and a total egg capacity of 36540. (See panel below for all species egg capacities)

This machine is used as a multi-stage setter. Constructed from high grade food safe materials and controlled using a user friendly reliable electronic digital controller and probes.

For ventilation a multi bladed removable plug in impeller fan ensures excellent internal air distribution. Heating elements are positioned directly in the fan air stream for maximum efficiency and water cooling pipes are position around the fan to aid an even temperature throughout the machine.

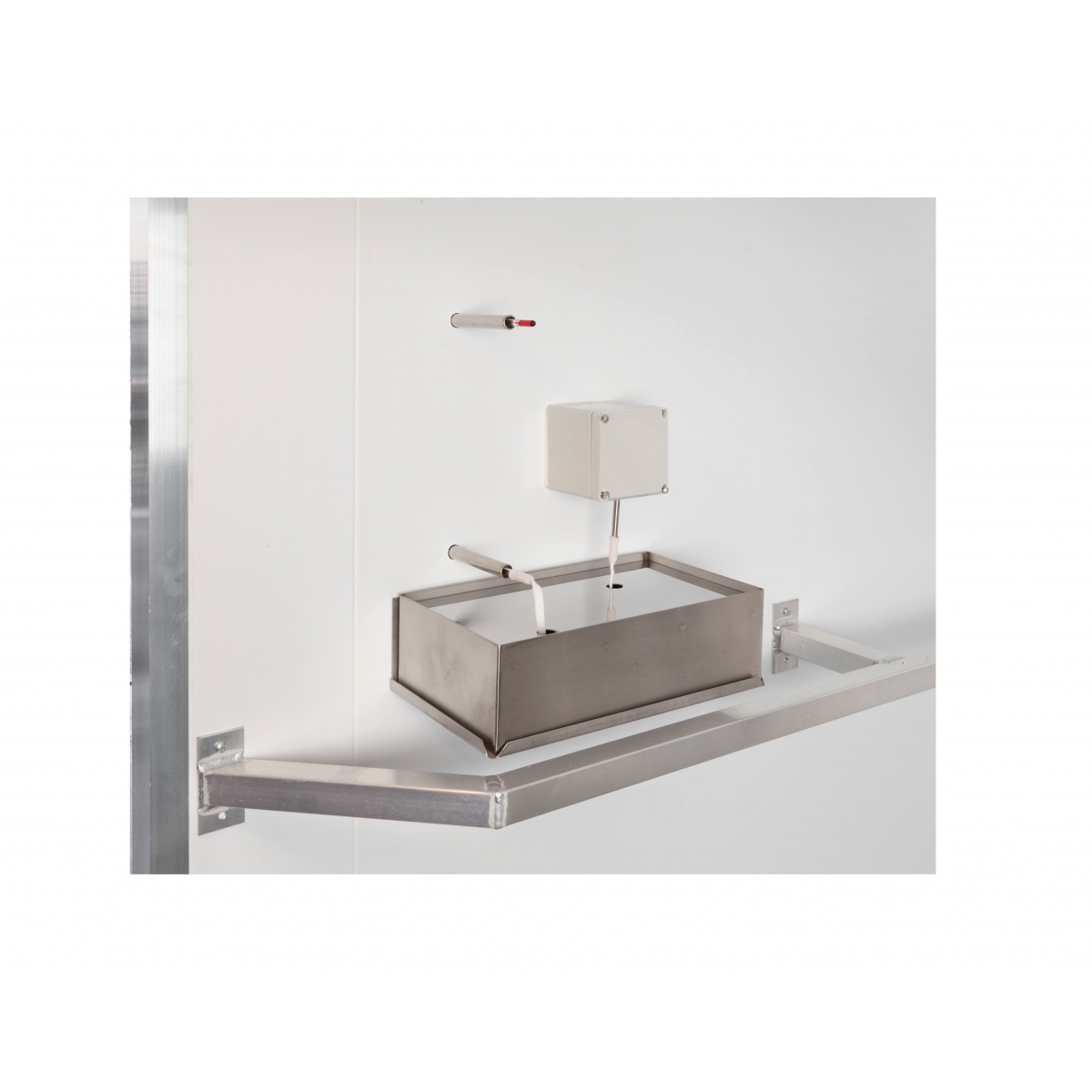

The automatic spray humidity system which is designed to produce just the right amount of humidity to suit the machine’s needs is controlled by a wet bulb probe for accurate measurement. The humidity jets are positioned under each fan for rapid humidification ensuring constant humidity throughout the machine.

The automatic turning system ensures that the eggs are turned every hour, The wheel-in trolley is constructed from lightweight aluminium, with low friction design pivot points and four swivel castors for maximum ease of mobility. A linear drive actuator mounted on the bottom of the trolley turns trays from one side to the other and a micro switch attached to the turning arm activates a counter in the control panel to confirm how many times the trolley has turned.

The machine comes with a built in high temperature and low temperature alarm system as well as a backup high temperature contact thermometer for calibration. It also has three spare connections with in the control panel to allow an external/mobile dial up alarm system to be connected to it.

All utility supplies are connected on the top of the machine and so enables for numerous machines to be erected next to each other. A mains water supply is required for the cooling and humidity and an electrical supply via plug or isolator.

All machines are easy to clean by removing the trolley and fan this leaves an empty cabinet and so accessible inside with pressure washer etc. (hold lance end minimum 14” away from sides and components).

All of our Setters and Hatchers are manufactured using the best quality materials and workmanship in Bristol, United Kingdom and come with a 1 year parts guarantee.

Our customer service and back up service is second to none with a 24 hour telephone number for out of office hour’s emergency contact.